Imagine a multinational PCB supplier found that its sub suppliers in emerging markets were not adhering to robust security protocols, resulting in unauthorized data sharing and weak cybersecurity practices. What is the risk?

Implementing ISO 27001-2022 in the PCB industry goes beyond theory—it creates a competitive edge by ensuring companies have tighter control, advanced security measures and prevents data leaks. Companies that invest in ISO 27001-2022 not only protect sensitive data but also gain greater operational control, making them more secure and better prepared for emerging challenges.

Here, we present a series of “what if” scenarios that demonstrate how ISO 27001-2022 compliance can transform the PCB supply chain.

Note: These scenarios are based on hypothetical situations intended to spark ideas and illustrate potential benefits, not on specific documented cases.

Thought Example:

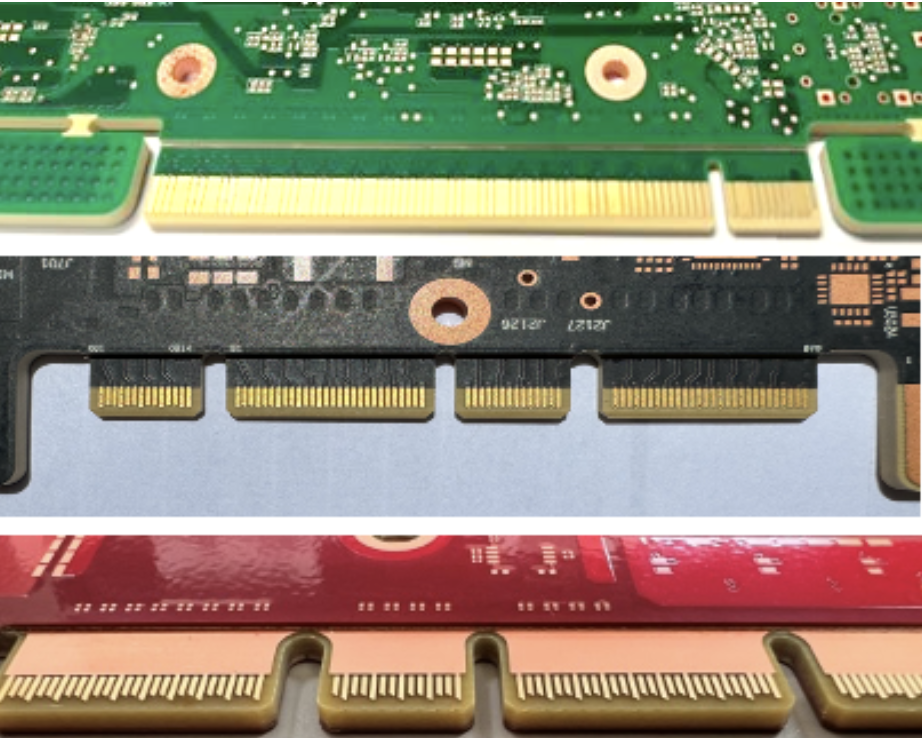

Strengthening Supply Chain Security for a Multinational PCB Supplier

So, back to the: What if?..

Imagine a multinational PCB supplier found that its sub suppliers in emerging markets were not adhering to robust security protocols, resulting in unauthorized data sharing and weak cybersecurity practices.

How could the company act, and how could ISO 27001 certification provide security?

Imagine that the supplier implemented ISO 27001 with a focus on:

- Supplier Risk Assessments: Evaluated sub suppliers’ security practices against ISO 27001 standards.

- Contractual Obligations: Required all suppliers to implement minimum security standards and undergo regular audits.

- Continuous Monitoring: Deployed real-time monitoring tools to detect and address anomalies in subcontractor data exchanges.

What could have been the outcome:

The supplier strengthened its supply chain integrity, ensuring secure collaboration and compliance with international regulations. This proactive approach also allowed them to expand their customer base to industries with strict security requirements, such as aerospace and medical devices.

If you found this interesting, please take a look at the first example in the What if? series.