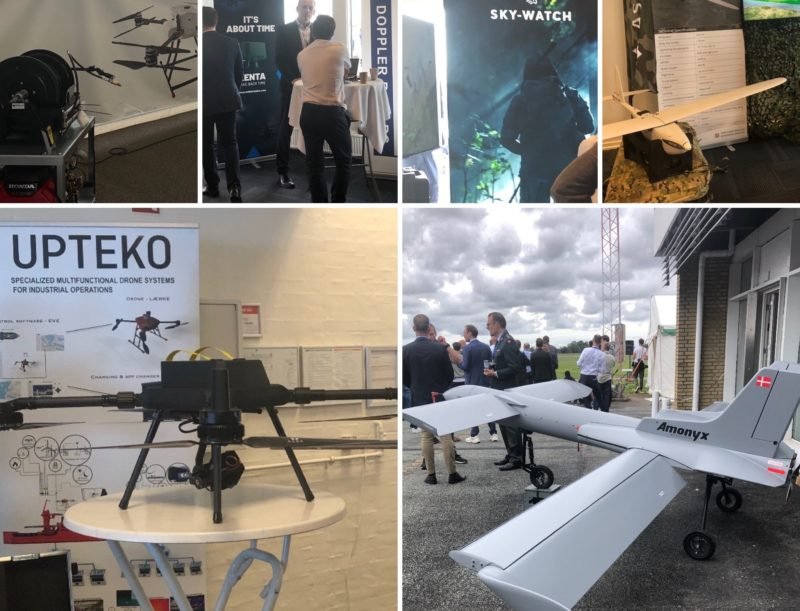

Late August we visited the local International Drone Show (IDS) at HCA Airport in Odense, Denmark.

Drones are here to stay, and the technology is continuously evolving. As always, experience new drone technologies in action, networking and listen to some of the biggest players in Denmark & Europe’s drone industry, is always enriching.

“Being a spearhead in new technologies is of paramount importance for us, serving as a printed circuit partner for multiple drone companies. Firstly, the drone industry is characterized by rapid technological advancements, and staying at the forefront ensures that we can meet the evolving demands in the industry”, says Sales Manager Denmark Torben Hajslund.

The event is a unique meeting place for drone companies and end users from Denmark and abroad, to discuss the latest drone innovations and explore new application potential. It attracts hundreds of visitors to experience live demos, visit the expo and gain new insights from researchers, developers and end users on key topics.

“As drone companies seek to gain a competitive edge by incorporating the latest innovations into their products, a Printed Circuit partner that consistently offers state-of-the-art solutions becomes invaluable”, says Hajslund.

A few tips before you start designing your new drone, from a printed circuit perspective.

- Size and Weight Constraints: Drones often have size and weight limitations, so it’s essential to design PCBs that are compact and lightweight. A crucial point in this regard, is to hink about finish copper thickness and plating requirements, as this will affect weight. Reducing the overall weight of the drone, will improve its maneuverability, and extend its flight time.

- Signal Integrity: Drones rely on various sensors, cameras, and communication systems that require reliable signal transmission. Properly manage signal integrity to minimize interference, noise, and signal loss. Use techniques like impedance matching and proper ground planes.

- Power Distribution: Efficient power distribution is critical in drone design. Ensure that the PCB design allows for the proper distribution of power to the various components, such as motors, sensors, cameras, and communication systems.

- Thermal Management: Drones generate heat during operation, especially the electronic components and motors. Incorporate effective thermal management solutions.

- Material Selection: Drones may be exposed to harsh environmental conditions, including moisture, dust, and extreme temperatures. Choose PCB materials and coatings that are resistant to these elements.

- Compliance with Regulations: Drones are subject to various regulations and standards, especially when it comes to radio frequency emissions and safety. Ensure that your PCB design complies with relevant regulations in your region.

- Testing and Prototyping: Thoroughly test and prototype your PCB design to identify and address any issues before mass production. This can save time and resources in the long run.

We assist many of the market leaders within drone technology, feel free to reach out to us for a fruitful discussion on printed circuits for drones. Together we can fly higher.